CO2 Cagua Project

Client: Cervecería Regional C.A.

Country: Venezuela

Plant: Cagua

Production Type: Beer and Malt

Description:

In order to have available CO2 permanently for its process, Cerveceria Regional acquired an automatic CO2 generation plant.

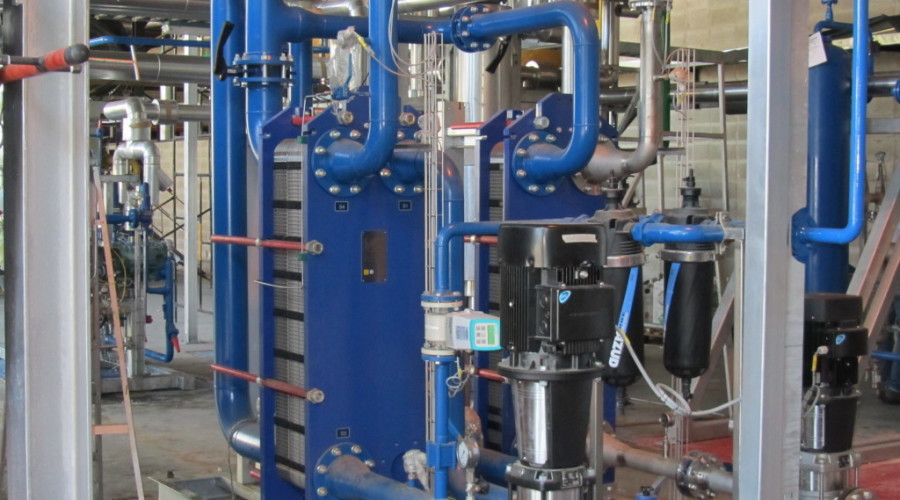

The CBU-1000 produces 1.000 kg/h of liquid CO2 from the combustion of natural gas in a tube boiler.

Once the CO2 is produced, it is separated from other gases by absorption in monoethanolamine (MEA) followed by purification in patented process by Union Engineering, called NOx-flash®, that eliminates the use of potassium permanganate which is used in the conventional technology.

Once the CO2 gas is separated, purified and concentrated it is compressed, carbon filtered, dehydrated, liquefied and distilled to obtain a purity of 99.99% with max 5 ppm of oxygen, which is used for human consumption.

Applied solution:

• Carbon Dioxide Generation Plant CBU-1000